- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

Company: Kalashnikov Izhevsk State Technical University

Author(s): Ibrahim Ibrahim Nizar

NI Product(s) Used: LabVIEW, Control Design and Simulation, Robotics Module

Industry: Robotics, Research

The Challenge

Addressing the dynamic model of the 11-DoF robotic arm prototype which is intended to be installed on the drone for executing remote actions. comparing fundamentally to the popular aerial manipulators, this 2nd generation could do actions like human's actions, that would be more close to people: clients or users, easy to understand the intent of actions, predict next ones, teaching new motions. The goals: Rescue and emergency, help remotely, chef applications, medical services, disabled people, delivery and so on.

The Solution

Determining the dynamic of robots is important to solve the subsequent issues in control and application. but it is difficult somehow when the robot is tree-like and has a high degree-of-freedom. The proposed aerial manipulator was considered as a complex engineering model because it consists of 28 degrees of freedom and described as a human-like arm. therefore, it was divided into two parts as follows: arm part and hand part, this within two principal frames, 28 joints and 23 links as shown in the figure below.

Aerial Manipulator 1st prototype

Now, in order to get the parameters of the kinematic model accurately, I used the item <Acquire Kinematics Parameters VI> in Palette: Serial Arm Definition VIs in the robotics library in LabVIEW. This tool depends on the XML file generated from Solid-works and outputs a D-H table. moreover, by setting the dynamic parameters (see figure below) the manipulator object will be ready to the control part. this figure presents the arm part of manipulator and the hand-part is also done the same way. so we will get six tables of D-H.

The Mathematical Solution

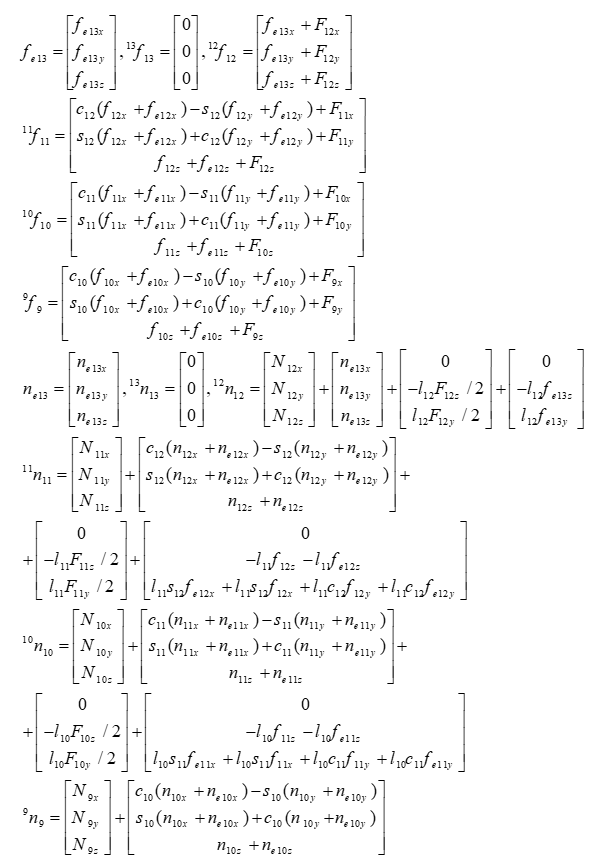

The dynamic equations were introduced for computing the required torque vector of torque space . these calculations depend on position, velocity, and acceleration of system's angles of joints by taking into our consideration external forces and moments on the links. for simplicity, the whole dynamic system was divided into two parts according to the workspace. arm's serial motion regarded to basic shoulder frame, and fingers' parallel motion regards to basic hand frames. the iterative dynamic Newton-Euler formula was applied to model the whole system by taking into our attention that each link is a rigid body has a designated center of gravity, mass, and inertia called mass distributing. the friction's factors were involved as Coulomb and Viscous. there are the classical formulas which are iterative outward and inward as follow:

Here, because of the manipulator is aerial, it is subject to disturbances of effects as aerodynamic as wind and so forth, so some formulas were developed which took into consideration added external forces and moments on the links as follows in figure below, these formulas didn't yet implement in LabVIEW robotics. now the research is going to prove it in the next studies.

Where τ is the n×1 vector of joint torques furnished by the actual actuators, and θ is the n×1 vector of joint positions, the matrix M(θ), is a n×n, symmetric, positive definite matrix called manipulator mass matrix. The vector V(θ,θ') signifies torques resulted from centrifugal and Coriolis forces. Whereas the vector G(θ) denotes the torques arises from the gravity forces, F(θ,θ') expresses the torques resulted from frictions forces and finally D(θ) represents the torques of disturbances induced on each link. this mathematical relation furnishes a clear perception about the variants affected the motion of manipulator as gravity, centrifugal, Coriolis, mass, and friction. moreover, it decreases the complexity when studying the motion with ignoring the angular acceleration as suggested previously in order to conclude a control mechanism with the Jacobean relation. the mechanical system is affected by frictions which are around to 25% of the required torque for each joint caused by a significant gearing mechanism. the following formulas exhibit two types of frictions such as Coulomb and viscous according to position and velocity of each angle.

The inverse dynamic equation was presented in LabVIEW as a function:

As shown in figure above, the dynamics here depends on gravity and external forces affected on the last link. we can use other VI in the Palette: Dynamics VIs which depends on inertia or Coriolis forces but it still doesn't take into account the external forces on the links. next we will derive mathematical equations of manipulator with external forces as a disturbances. these forces is acting as wind, aerodynamics or other actions could affect the motion the links in the air.

The Solution

The following sections proffer a dynamic study of arm-part. The whole study begins with the basic arm's frame to determine the required torques in order to move the basic hand's frame to a specified location in terms of joint motion space. the next figure illustrates the external forces and moments which reflect the real disturbances behaving on the links. The dynamic of hand-part consists of five dynamical investigations which are analogs but the only difference is the physical parameters. the hand-part wasn't explained in this study. The following figure illustrates the forces and moments acting on the links for the arm-part in order to sketch the dynamical models.

Based on our method with developed dynamic Newton-Euler formulas by taken into our consideration the external forces and moments we can conclude the dynamic model as follows:

The dynamic of hand-part consists of five dynamical investigations which are analogs but the only difference is the physical parameters. it is apparent that the thumb has a different structure among others so it’s model would be more reduced. the following figure illustrates the forces and moments acting on the links for the fingers in order to sketch the dynamical models.

Mathematical equations of the thumb finger

Mathematical equations of the thumb finger

Conclusion

In accordance with the dynamics and its complexity, The LabVIEW program and especially Robotics Module were considered as an ideal tool regarding the easy way in understanding the dynamics, solving it and finally developing it. the amazing in this subject at all is the ability to do the experiments easily by sending the joints data to motors directly using RIO devices through control system on FPGA chip and drive them in a parallel way.

The next case study will discuss the reduced model of the manipulator and its dynamics.

This is the first launch of the prototype.

The first prototype of this manipulator after enhancing the hand.

Additional Materials

https://mech.novtex.ru/jour/article/view/535

https://elibrary.ru/item.asp?id=29162302

http://izdat.istu.ru/index.php/vestnik/article/view/4044

https://www.youtube.com/watch?v=Is0R3t1ZI9I

http://robotrends.ru/pub/1916/skolkovo-robotics-2019-manipulyator-dlya-drona

Author Contact Details

Ibrahim Nizar Ibrahim

Research Engineer

https://www.linkedin.com/in/ibrahim-

Kalashnikov Izhevsk State Technical University

Pesochnaya, 38A, Izhevsk, ISTU, Department of Electronic and Electrical Engineering

Russian Federation

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Cool project. Opens up a lot of exciting new use cases for drones. Thank you for sharing Ibrahim!

Senior Marketing Engineer, National Instruments

Connect on LinkedIn: https://www.linkedin.com/in/richard-roberts-4176a27b/

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report to a Moderator

Very cool project. I am rusty on my dynamics I'm going to have to read through this a couple times and see what you did. Way to go on calculating all the forward dynamics. I am fairly new to National Instruments but graduated in mechnical so I will have to play with this robotics library. I didn't even know it existed.