- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

Contact Information

| University | Fachhochschule Südwestfalen, University of Applied Sciences, Iserlohn, Germany |

| Department | Computer Sciences and Natural Sciences |

Faculty Advisors | B. Mütterlein U. Reitz |

Team Members | A. M. Carvalho M. S. Grieb S. Hoffmeyer M. Lastowski S. Meyer P. Ochtendung M. Richter F. Wilbers |

| Primary Email Address | muetterlein@fh-swf.de |

| Primary Telephone | +49 2371 566 311 |

Project Information

Project Title: Bioengineering with LabVIEW

Engineering Domains

- Control Design, Mechatronics & Robotics

- Signal & Image Processing

- Bioengineering

- Biomedical Applications

Part List

| NI components | Sensors | Actors |

|---|---|---|

|

|

|

The Challenge

Well suited for the application of problem oriented learning is the course ”Data Acquisition and Signal Processing“ at the University of Applied Sciences in Iserlohn, because the intensive cooperation between the involved laboratories allows the definition of interdisciplinary projects with the main goal of laboratory automation. As an example for this aim, we will present the project ”Bioreactor“. As no constraints existed for this project (Fig. 1) the tasks for the students were the choice of the right hardware components, signal conditioning, image processing, integrating of external code and the development of a reliable and scalable software architecture.

Fig. 1: Constraints at project start

The Solution

Introduction

While restructuring the first degree of the course of studies ”Bio- and Nanotechnologies“ at the University of Applied Sciences in Iserlohn the improvement of interdisciplinary cooperation and problem orientated learning was kept in mind. Exemplary is the compulsory elective ”Data Acquisition and Signal Processing“. The project orientated courses goal is the laboratory automation and signal processing, whereas the deliverables could later be used educationally in other laboratories. Thus the students should develop their own experimental setups (i. e. gas-phase chromatograph, electro potentiostat, dip-coating machine). Besides some dozen smaller projects (i. e. measuring light speed, semiconductor measurement technology, frequency response of a speaker), the students have the possibility to define projects on their own or along with other in the course of studies involved colleagues in their respective laboratories (see acknowledgments). Hence result generally ambitious tasks, which cannot be realized within the temporally narrowed bounds of a course. Exemplarily the project ”Bioreactor“ is presented, which was realized by eight students within the bounds of four semester periods per week.

Project Bioreactor

A bioreactor for producing microorganisms or pharmaceutics implies the monitoring of parameters like pH-value, oxygen-concentration, temperature and cellconcentration as well as partially controlling them by i. e. titration of acids or bases.

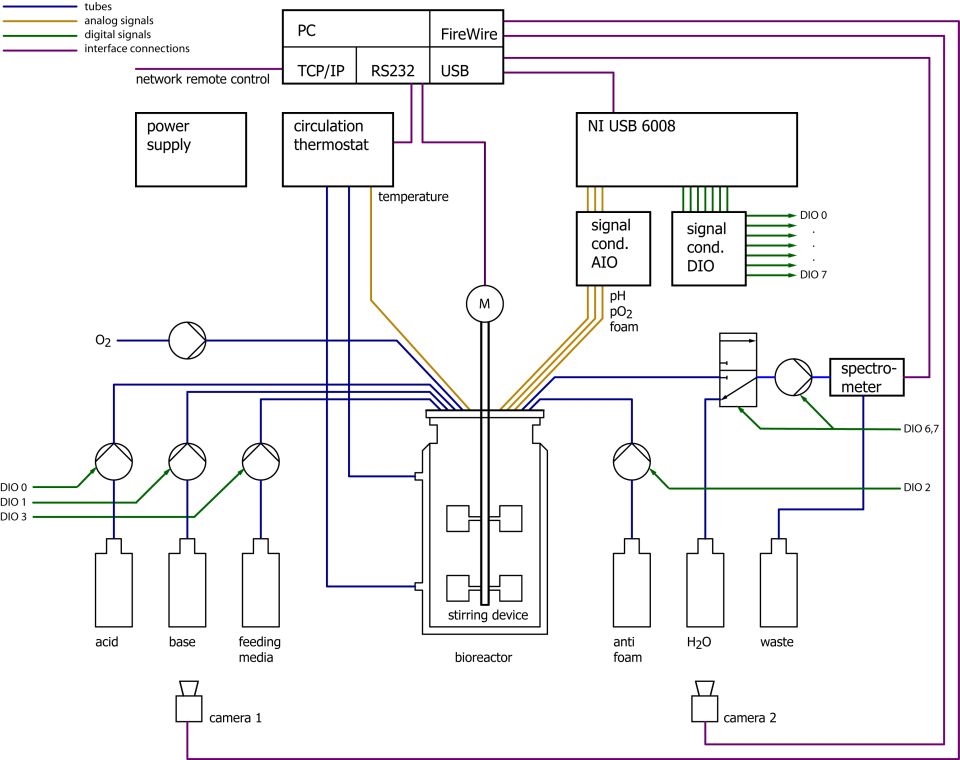

Figure 2 shows the bioreactor´s block diagram. The supply bottles´ fill levels are monitored by image processing whilst the medias are delivered to the reactor by flexible-tube pumps. The digital outputs of the data acquisition box USB-6008 are used to control the pumps, as the analog inputs are used to acquire the sensor signals.

The optical density is determined using a spectrometer, whose measuring cell can be rinsed with water by a 3/2-way valve. The circulation thermostat and the stirring device are adressed via RS-232 interfaces. The oxygen supply is handled by a commercially obtainable pump for aquariums. Finally the reactor is remote controllable via network.

Fig. 2: Schematic diagram of the bioreactor

No concrete specifications were given at the project´s start (Fig. 1), so that the students were confronted to almost all relevant topics of laboratory automatisation, the choice of the needed components, like appropriate sensors (including their calibration), signal conditioning, data acquisition with LabVIEW and the conceptual design of an adequate software structure. Covered tasks are therefore

- mechanical construction

- data acquisition

- sensor specification

- signal conditioning

- controlling actors

- machine vision

- software development

- finite state machine

- error handling

- GUI-design

Figure 3 shows the project’s achieved result. Below is given a closer look to several of the project’s tasks.

Fig. 3: Successful realization of the project goals

Mechanical construction

Designing the mechanical construction a framework made of stainless steel square tubes was preferred. This allows the system´s modular construction, so that components can be added as and when required. Additionally the open framework has the advantage of revealing the reactor´s functionality to practical participants.

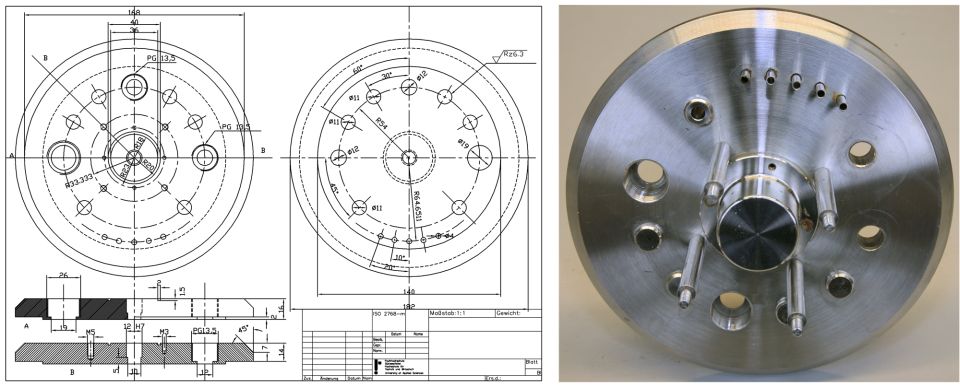

Besides the construction allows to be easily autoclaved. To ensure sterility during operation, load transmission from motor to stirrer is made up by magnetic coupling.The engineering drawing for the reactor cover was made in AutoCADr (Fig. 4.a). The cover was crafted by the university’s machine shop (Fig. 4.b).

Fig. 4: Reactor cover a) engineering drawing, b) realization

Data acquisition and pump control

The data acquisition box USB-6008 from NI is preferentially used in educational data acquisition because of its limits like low sample frequency and low internal resistance, which can benificially be used to point out problems in measurement technology, that high performance measurement devices won´t show. For example reading-out a pH-Sensor requires a measurement device´s internal resistance to be greater than 50G (USB-6008: 144 k) and measuring temperature with a PT100 requires a current source which is not provided by the box. To protect the boxes´ digital outputs, the relais with recovery diode are controlled via optocoupler. To ease software handling, the user can specify the supply rate in ml instead of pump turns.

Signal conditioning

An exemplary gaze on the pH-sensor should illustrate signal conditioning. Customarily used pH glass electrodes are highly resistive. Thus an impedance converter is necessary (Fig. 5.a). A TL071 operational amplifier with 1012 input resistance is used. The additional amplification is used to to level the sensor´s signal to the DAQ-card´s measurement range. The circuit gets interference-prone by it´s high input resistance, so that it has to be payed attention to short conductive paths and applicable pcb-tracks. Auxiliary capacities C3, C4 at the input and C1, C2 at the output as well as resistor R3 are necessary for noise suppression. The circuit has been realized in SMD technology (Fig. 5.b).

Fig. 5: Signal conditioning for pH glass electrode a) schematics, b) SMD PCB

Spectrometer and embedding of external code

By measuring the optical density of the media with a spectrometer, cell count per ml can be derived. Therefor a spectrometer type spec-i is used. As no LabVIEW driver exits for this type of spectrometer, it had to be developed within the project. This has been realized by integrating external C libraries by Call Library Function Node. Calibration took place in a Neubauer counting chamber.

During the projects progression multiple experiments revealed that the spectrometer suits for acquiring several other measurands. For instance it is possible to measure the medias temperature. Furthermore the usage of adequate dyes allows to measure pH and pO2 values whilst the determination of glucose concentration can be conducted with enzymatic tests. This establishs the prospective possibilty of measuring all the bioreactor´s measurands with a spectrometer, so that usage of costly, high-maintenance sensors can be omitted.

Interfaces

Controlling stirring device and circulation thermostat via RS-232 and VISA-sessions in LabVIEW ran smoothly and obviously was implemented faster than explaining the functionality of the RS-232 interface. Because the circulation thermostat type Julabo F25-HD contains an external PT100 sensor and controls temperature with an accuracy of ±0.1 °C, the control path´s complex analysis and temperature control by computer was renounced.

Machine vision

Minimal distance from camera to supply bottles has been achieved by using a short focal length lense (f = 2.8 mm, Fig. 6). The expected distortion could be tolerated, because the image calibration by the bottles´ level indicators is sufficiently exact. To avoid reflections on the bottle influencing the image, the bottles are backlit with panel lights.

Fig. 6: Camera arrangement

The Image Assistent application facilitates the efficient introduction into industrial image processing. Exemplarily the determination of the supply bottles´ fill levels is presented. To FireWire cameras are used for image acquisition. Figure 7.a shows the image of a supply bottle. After adjusting brightness and contrast (Fig. 7.b), inverting the image with the logical function [not or] (Fig. 7.c), selection of image section (Fig. 7.d) and levelling the threshold (Fig. 7.e), the particle analysis (Fig. 7.f) delivers the four fill levels´ coordinates and the fill levels themselves.

Fig. 7: Image processing steps

Software architecture

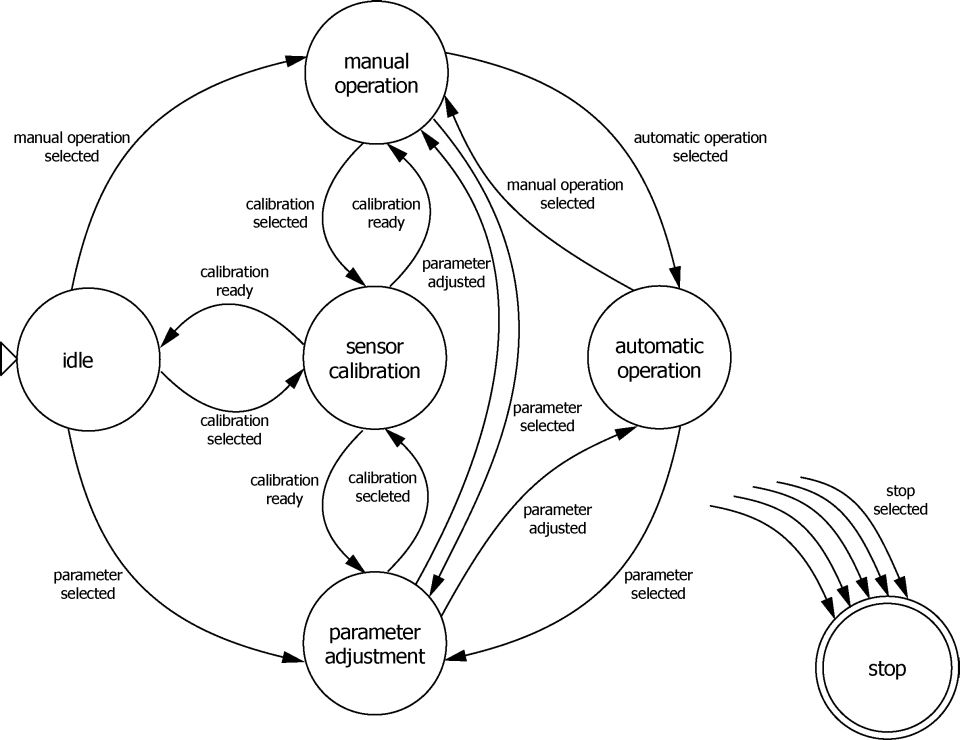

A good portion of project time has been spend on developing an adequate state machine model (Fig. 😎 and its implementation in LabVIEW. The realization in LabVIEW was made by creating a state event matrix for sequential control. All variables of each project part were merged in clusters that all were merged in another cluster with all system variables. For error handling a further cluster was added. All clusters and Enums are implemented consequently as Strict Type Def. This structure can differ slightly in subprograms.

Fig. 8: Simplified state diagram of the bioreactor

Figure 9 shows the main programs software architecture composed of a while loop and a case structure. At program start the case ”Initialize“ is executed in which besides other settings all shift registers are initialized. In every state the machine calls regularily the case ”Check Inputs“ to detect events and when indicated executes the adequate action and switches to next state by interpreting the state event matrix.

Fig. 9: Event handler in the block diagram of the main VI

Conclusions

Realizing this project took place by generally solving subproblems in two head teams, whilst it was taken care of a good communication between all teams, so that at every point of time all project members were briefed about the project´s progress. With about a hundred system variables the software´s complexity was high enough to reasonable apply concepts of software technology. Remarkably, problems integrating software components in the main program existed at no point of time.

With exception of mechanical construction and integration of the pO2 sensor all tasks were accomplished four weeks prior to semester´s end. In the process it arose, that realizing such project at this amount and complexity factor is possible with fourth semester students. The time provided by class schedule is not sufficient for this kind of project oriented learning. It could just be realized in small groups, because the efforts in time to support the students is immensely high and cannot be realized with the personal resource of Universities for applied sciences.

By close coordination and cooperation between different fields of teaching, actually an interdisciplinary education is achieved. Omitting lectures, auditoriums and written exams results in higher motivated students, which lastingly improves their understanding in technical and natural scientific coherences. So even after restructuring degrees from diploma to bachelor a high learning success can be achieved, when courses are adapted to the changed constraints and are developed properly.

Acknowledgements

Thanks go to the professors and staff of the divisions microbiology, biotechnology and biomaterials, applied computer science, electronics, chemical nanotechnology and life sciences as well as to the machine shop for technical and substantial assistance without whom the realization of the project had never been possible.