- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report to a Moderator

Group M2 – EMG Glove for Muscular Dystrophy Patients

Final Design Project Lab Report

Introduction

Our design project’s goal is to help people with muscular dystrophy. This is a degenerative

disease which severely reduces functionality of the patient because of increase in muscle tissue friability.

Our project is focused on hand movement. The main aim is for the patient to be able to move his or her

arm, and achieve normal gripping ability. For the design a glove with cables attached to the fingertips will

be used. The fingers are closed by an actuator and opened passively by rubber bands. The motor unit is

turned on/off utilizing a lab view program controlled by EMG signals taken from the patients arm.

Experimental Setup

The project consists of three main parts: EMG signal acquisition, LabVIEW processing and

Glove assembly. The EMG signal is taken from the finger extensor muscles on the forearm of the patient.

Those are the muscles that would normally be used for a gripping motion too. The signal is then amplified

and filtered using a band-pass filter with a total gain of 3000 and cut-off frequencies of 18 Hz and 450

Hz. In LabVIEW, the EMG-Signal is further processed and a band-stop filter is implemented from 59 Hz

to 61 Hz to filter out 60 Hz power line noise. The signal DC offset is also removed in the VI. One EMG

signal is used to toggle between the mechanical relays, the other signal outputs to the digital outputs of

the DAQ and is used to activate the actuator by delivering a 5V DC. The digital outputs are used because

with analog inputs the time lag is too big with analog outputs. The signal controls a MOSFET which

delivers the required current to the selected relay. The actuator is thus directly connected to the switches.

When the actuator, which is placed on the forearm, pulls on the cables attached to the fingertips of the

glove the hand is closed in a grabbing motion. The cables are run through tubing attached to the glove, so

that they are not in the way when the person wants to grab something. To reduce the number of cables

running along the hand we connected two fingers to one cable. The cable of the thumb is run over a

pulley in order to change the direction. On the other side of the hand rubber bands are attached to

passively open the hand. The wrist is stabilized with a wrist brace, without which the wrist would move

instead of the fingers. For a better grip another glove could be worn over this one. An overview of the

glove and electronics can be found in appendix A and B respectively.

Results

During the initial testing phase, we observed multiple sources of lag and error. The first of those

was that the LabVIEW software had a delay in updating the LED vis-à-vis the actual value of the local

variables, which was rectified when we switched the output from analog to digital. We also observed that

the DAQ output was insufficient to power the mechanical relays on its own (limited to 5V) and

necessitated the use of two MOSFET based systems, which allowed us to use the digital outputs as

toggles while drawing power from the 12V DC car battery. Relative motion between the actuator and

forearm was also observed and ameliorated as much as possible by the use of duct tape. A thumb brace

was implemented to limit the motion of the thumb to two dimensions.

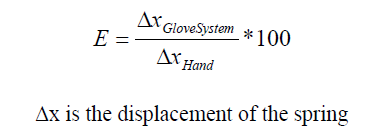

For the glove validation we used a spring system (see appendix C). The spring constant for each

spring was calculated using the Instron 3366 Load Frame to be 861N/m (see appendix D for linear

regression). Using four springs, all with the same spring constant, we created 6 test cases using a

combination of series and parallel configurations (see appendix E for different configurations). To

perform ‘efficiency’ (

E) measurements we measured the displacement achieved by a healthy subject’s

forearm contraction against the spring system vs. that achieved by the actuated glove without the use of

the subject’s muscles. As expected there were mechanical losses in the glove that created an

E of 85.5%

(see appendix F).

Any reduction in efficiency is mainly due to the motion of the wrist and movement of the actuator relative

to the forearm.

The first of our demonstrations of dexterity involved the transport of a Styrofoam cup filled with

water, which was chosen given the relative fragility of the cup material. The criteria for success included

not crushing the cup and not spilling the water in the process, which were met. The other test for dexterity

was the use of scissors to cut duct tape, which was achieved in two cycles of actuation.

While we have no quantified data with regard to the reliability of our system, we did perform our

dexterity tests and efficiency measurements multiple times over the course of multiple days and observed

the same results with no malfunctioning of the device.

Discussion and Conclusion

Overall we were able to achieve the desired targets. The person with the EMG-Electrodes was

able to open and close the hand of the person wearing the glove. In an actual scenario this would be the

same person, however in the interest of simulating conditions of atrophy a separate person was assigned

glove control. It was also possible to control the actuator with enough sensitivity to achieve the dexterity

required for the aforementioned Styrofoam cup and scissor tests.

Sources of error in this experiment include crosstalk between the two locations where the

electrodes were placed, mechanical losses and software lag. Increasing the distance between the

electrodes to the point where they are placed on different portions of the arm, could reduce crosstalk, but

we decided against this to maintain a greater semblance to normal hand use. By using digital instead of

analogue outputs we were able to reduce the majority of the time delay. Mechanical losses arise due to the

fact that we were using a two-inch actuator, which for normal range of motion in a hand is not enough.

This error was accentuated by a forward movement of the actuator and a bending motion of the wrist

during contraction. To fix these issues, a longer actuator placed more firmly on the arm would suffice.

Application

With regard to the possible future directions the development of our device could take, we would

like to incorporate the independent motion of the individual fingers and 3D motion of the thumb in an

effort to increase manual dexterity. We would also aim to condense the power supply system as well as

modify the actuator to draw less spike current, allowing us to explore alternate sources of power. The

device in question serves as not only a very useful tool for rehabilitation and/or assistive aid; it also has

the potential to augment user strength thereby reducing fatigue for labor intensive tasks. In an overview

sense, the healthcare provider could recommend our EMGlove to enable people with mild to moderate

symptoms of muscular dystrophy to restore day to day functionality, improving the patient’s quality of

life.

Attachment: Original Report